Semi trailer-sized machines could provide a unique solution to a major source of the fossil fuel industry’s methane problem. Rather than flaring or venting the planet-warming gas into the atmosphere, the machines can convert it into methanol, a useful industrial material and fuel.

Florida-based startup M2X Energy has raised more than $20 million from investors, including Bill Gates-backed Breakthrough Energy Ventures, to build its gas-to-methanol trailers. The methanol plants on wheels could help reduce methane emissions at remote locations like North Dakota’s Bakken shale play where gas is often produced as a byproduct of oil and a dearth of pipeline space means the fuel isn’t transported to market.

In the US, more than 286.7 billion cubic feet of gas was wasted through flaring or venting in 2021 from upstream oil and gas facilities, although the actual figure is likely far larger because some releases don’t get reported and the total doesn’t include emissions from some key producing states that don’t track the data. Even so, that’s enough gas to supply roughly 4.9 million US homes for an entire year. Globally, about $15.9 billion worth of gas was wasted through flaring last year, according to the World Bank. The practice also damages the climate.

“The idea is to tackle the problem of flaring and venting, especially in the oil and gas industry, which is one of the biggest problems as far as carbon emissions and methane emissions are concerned,’’ said Max Pieri, chief executive officer of M2X, which currently has a demonstration unit hooked up to a well in North Dakota.

Methane, which is made up of carbon and hydrogen atoms, is the primary component of natural gas and has a devastating impact on the climate. The invisible, odorless gas has more than 80 times the warming power of carbon dioxide during its first 20 years in the atmosphere. Although combusting the gas through a flare significantly reduces the climate impact, the practice isn’t optimal because it wastes fuel that would otherwise be sold and still contributes to global warming because the byproduct of burning it is carbon dioxide.

New studies also show that flaring may have a bigger climate impact than previously thought. Governments and industry have historically assumed that flares combust methane at a 98% efficiency rate. But scientists using airborne sampling across three US fossil fuel basins found flares effectively only destroyed 91.1% of methane. The new amount constitutes 4% to 10% of total US oil and gas methane emissions, according to a study published in Science last year.

Oil wells typically produce a mixture of crude, gas and water that are separated with heat. When an M2X trailer arrives on site, gas that is normally piped to a flare a safe distance away is diverted through a pipe. Although M2X’s initial demonstration project in the Bakken uses supplemental power and an external chiller to get data on power and chiller demand, future commercial units will be fully powered by the unit’s adapted internal combustion engine fueled by the gas stream.

Once inside the trailer, the engine oxidizes the gas to produce a mixture of hydrogen and carbon monoxide known as syngas. Methanol is produced by passing the syngas over a standard methanol copper zinc oxide catalyst.

The majority of the world’s methanol is made from natural gas or coal at large, centralized facilities where the fossil fuel is converted into syngas by heating it with steam in the presence of a catalyst. That process done at scale is cost-effective, even after paying for natural gas.M2X also plans to pay producers for gas, although prices could go to zero or drillers could even pay M2X depending on methane regulations, according to the startup. The company declined to disclose its production costs, although Pieri said it “compares well” with conventional approaches.

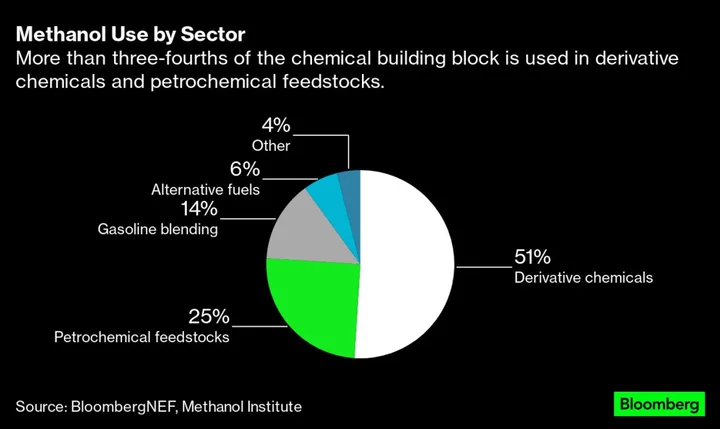

Methanol is primarily used as a feedstock for producing chemicals such as formaldehyde, and it’s a building block in thousands of products from car parts to paint to construction materials. Roughly 98 million metric tons of methanol are produced annually, according to the Methanol Institute.

But the compound could also play a significant role in the energy transition because when combusted as a fuel, it generates less CO2 and particulate matter than many other fossil fuel-derived products. That means it could help curb the climate impact of sectors like marine shipping. Although about 20% of global supplies are currently blended into gasoline and used in alternative fuels, the chemical compound still has some challenges to reach widespread adoption because it less energy per liter when compared to conventional fuels like diesel.

While capturing fossil gas that would otherwise be flared or vented and using the fuel to produce methanol offers climate benefits, the approach can also harden reliance on fossil fuels, said Anastacia Davies, an analyst with BloombergNEF, which forecasts a substantial role for methanol made from renewables in the global energy transition.

“As a fuel, methanol derived from flare gas is better than methanol produced from fossil fuels, but not as good as methanol from renewable energy and direct air capture,’’ said Davies.

M2X isn’t the only company trying to solve the problem of wasted gas — and profit from it. Texas crypto miners have touted hooking up generators to run off gas that would otherwise be wasted as a means to power the vast computer arrays they use to create new Bitcoin. Others are looking at building data centers that can be powered using the surplus gas.

Read more: A Way to Halt Natural Gas Flaring Arrives on the Back of a Truck

But the natural intermittency of gas flows during production, weather conditions and volatile electricity prices can create challenges for those operations. M2X says that because each of its gas-to-methanol units can process between 35,000 and 120,000 standard cubic feet of gas per day, they can accommodate normal changes in flow from oil and gas wells. And because methanol is liquid at ambient temperature, it’s easy to store and transport.

M2X expects to deploy up to a dozen units over the next one to two years in oilfields in the US and internationally. The company’s business model in the US is to purchase stranded gas directly from operators, process it on-site and sell the methanol. Globally, the company expects to sell the units directly to energy producers.

“We are targeting all these places where there is no infrastructure to harvest the gas and put it on a pipeline,” said M2X’s Pieri.

--With assistance from Akshat Rathi.

(Updates paragraph 9 with the impact regulations could have on M2X’s business model.)